Call:

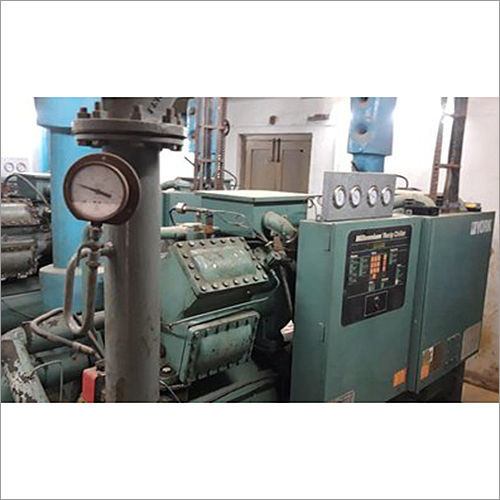

पà¥à¤°à¤¾à¤¨à¤¾ à¤à¤¦à¥à¤¯à¥à¤à¤¿à¤ वाà¤à¤° à¤à¤¿à¤²à¤°

पà¥à¤°à¤¾à¤¨à¤¾ à¤à¤¦à¥à¤¯à¥à¤à¤¿à¤ वाà¤à¤° à¤à¤¿à¤²à¤° Specification

- एयर फ्लो

- 2500 m³/hr

- मोटर

- 3 HP

- रेफ्रिजरेटिंग क्षमता

- 15 TR (Ton of Refrigeration)

- मटेरियल

- एप्लीकेशन

- Industrial Cooling Applications

- शर्त

- टाइप करें

- Water Cooled Chiller

- आयाम (एल* डब्ल्यू* एच)

- 1500 mm x 900 mm x 1400 mm

- बिजली की आपूर्ति

- 3 Phase, 415V, 50Hz

- वोल्टेज

- 415 V

- कूलिंग टाइप

- Water Cooled

- नोजल सामग्री

- Stainless Steel

- कूलिंग कॉइल सामग्री

- Copper

- पानी के प्रवाह की दर

- 150 LPM

- वाटर पंप मोटर

- Centrifugal Type, 2 HP

- नॉइज़ कंट्रोल

- Sound Insulated Compressor Mounts

- कम्प्रेसर

- Hermetic Sealed Type

- Chiller Capacity

- 15000 Kcal/hr

- Inlet/Outlet Connection Size

- 1.5 Inch

- Evaporator Type

- Direct Expansion

- Condenser Type

- Shell & Tube

- Mobility

- Heavy Duty Castor Wheels

- Weight

- Approx. 450 kg

- Temperature Range

- 5°C to 25°C Adjustable

- Overall Paint Finish

- Powder Coated Industrial Grey

- Protection Features

- Overload and Phase Protection

- Year of Manufacture

- 2018 (Approx.)

- Refrigerant

- R22

- Display Panel

- Analog Temperature Gauge

About पà¥à¤°à¤¾à¤¨à¤¾ à¤à¤¦à¥à¤¯à¥à¤à¤¿à¤ वाà¤à¤° à¤à¤¿à¤²à¤°

Over the years of dedication, we have been serving our clients with a quality tested range of Old Industrial Water Chiller in the market. It finds application for both industrial and commercial use. Chiller systems are essential for temperature control and cooling in several industries. Choosing the right kind of Old Industrial Water Chiller for process and space cooling can lower cooling costs, minimize downtime, and also help in improving operational efficiency.

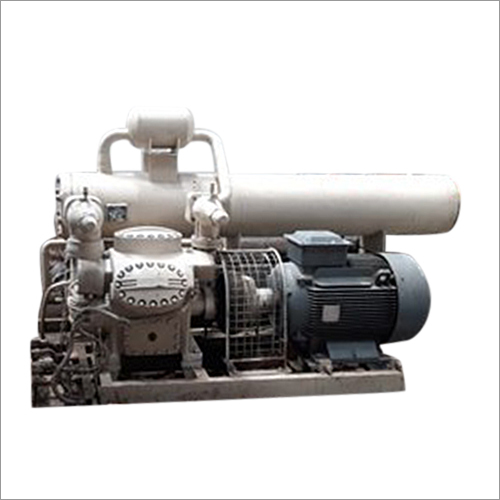

Specification

| Usage/Application | Commercial |

| Type | all type |

| Capacity | 2ton-400ton |

| Power | 410VAC |

| Model Name/Number | water chiller |

| Cooling Capacity | 2ton to 400 ton |

| Compressor Type | screw type |

| Material | Ms/GI |

| Brand | carrier ATR cool |

| Voltage | 410 volt |

Efficient Cooling Performance

Engineered for demanding industrial settings, this chiller can maintain water temperatures between 5C and 25C. The combination of a 15 TR capacity, high water and air flow rates, and a shell & tube condenser ensures optimal cooling efficiency for various processes.

Durability and Mobility

Constructed with a powder-coated mild steel body and sound-insulated compressor mounts, this unit is both robust and quiet. Heavy-duty castor wheels provide mobility, allowing easy repositioning within facilities despite its 450 kg weight.

Reliable and User-Friendly Operation

The analog temperature gauge allows for straightforward control and monitoring. Integrated overload and phase protection enhances safety, while the direct expansion evaporator ensures fast and reliable cooling for industrial applications.

FAQ's of Old Industrial Water Chiller:

Q: How do I adjust the temperature on this water chiller?

A: You can easily adjust the temperature within the 5C to 25C range using the analog temperature gauge panel provided on the chiller. This allows customization based on your process requirements.Q: What industries commonly use this water chiller model?

A: This industrial water chiller is suitable for a variety of sectors, including manufacturing, chemical processing, pharmaceuticals, and other areas that require precise temperature control for equipment or processes.Q: Where can I source replacement parts or servicing for this chiller in India?

A: Replacement parts and service are available through authorized dealers, distributors, suppliers, and service providers across India. Contacting the manufacturer or local distributor ensures access to genuine components and expert support.Q: What are the benefits of the shell & tube condenser and direct expansion evaporator?

A: Shell & tube condensers provide efficient heat transfer and durability, making them ideal for continuous operation. The direct expansion evaporator enables rapid cooling, improving system response and efficiency.Q: What protection features does the unit offer during operation?

A: The chiller is equipped with overload and phase protection, safeguarding the compressor and motor from electrical faults, helping prolong equipment life and maintain operational safety.Q: How is noise controlled despite the chiller's industrial size?

A: Sound insulated compressor mounts are used to reduce operational noise, making the chiller suitable for environments where noise limitation is important.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in Used Chiller Category

पुराना इलेक्ट्रिक वाटर चिलर

नॉइज़ कंट्रोल : Insulated Cabinet for Low Noise

शर्त : ,

वाटर पंप मोटर : 0.5 HP

कम्प्रेसर : Hermetic Sealed Type

नोजल सामग्री : Brass

मटेरियल : ,

ओल्ड वाटर चिलर

नॉइज़ कंट्रोल : Standard

शर्त : ,

वाटर पंप मोटर : Threephase AC Motor

कम्प्रेसर : Hermetic Reciprocating

नोजल सामग्री : Brass

मटेरियल : ,

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें